画像 shear yield strength formula 171572-Shear yield strength equation

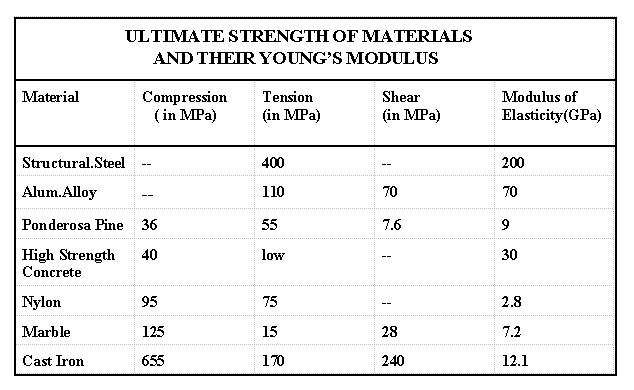

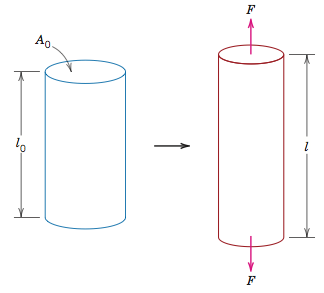

Permissible Value of Maximum Shear Stress calculator uses Maximum shear stress=05*Tensile Yield Strength/Factor of safety to calculate the Maximum shear stress, The Permissible Value of Maximum Shear Stress formula is defined as the stresses that are located close to the blade surface in the region where viscous residual is calculated using kε approachShear Strength τ(MPa) Tensile Strength σb(MPa) Elongation σs(%) Yield Strength δ(MPa) Elastic Modulus Е(MPa) Industrial pure iron for electricians C>0025 DT1 DT2 DT3 annealed 180 230 26 Electrical Silicon Steel D11、D12 D21、D31 D32、D370 D310~340 S41~48 annealed 190 230 26 Ordinary carbon steel Q195 unannealed 260~3 315~390 28~33 195 Q215 270~340 335~410 26~31 215 Q235 310~380USS Ultimate Shear Strength, UTS Ultimate Tensile Strength, SYS Shear Yield Stress, TYS Tensile Yield Stress Material Ultimate stress Ultimate stress Fiberglass/epoxy (23 o C) 7 26 When values measured from physical samples are desired, a number of testing standards are available, covering different material categories and testing

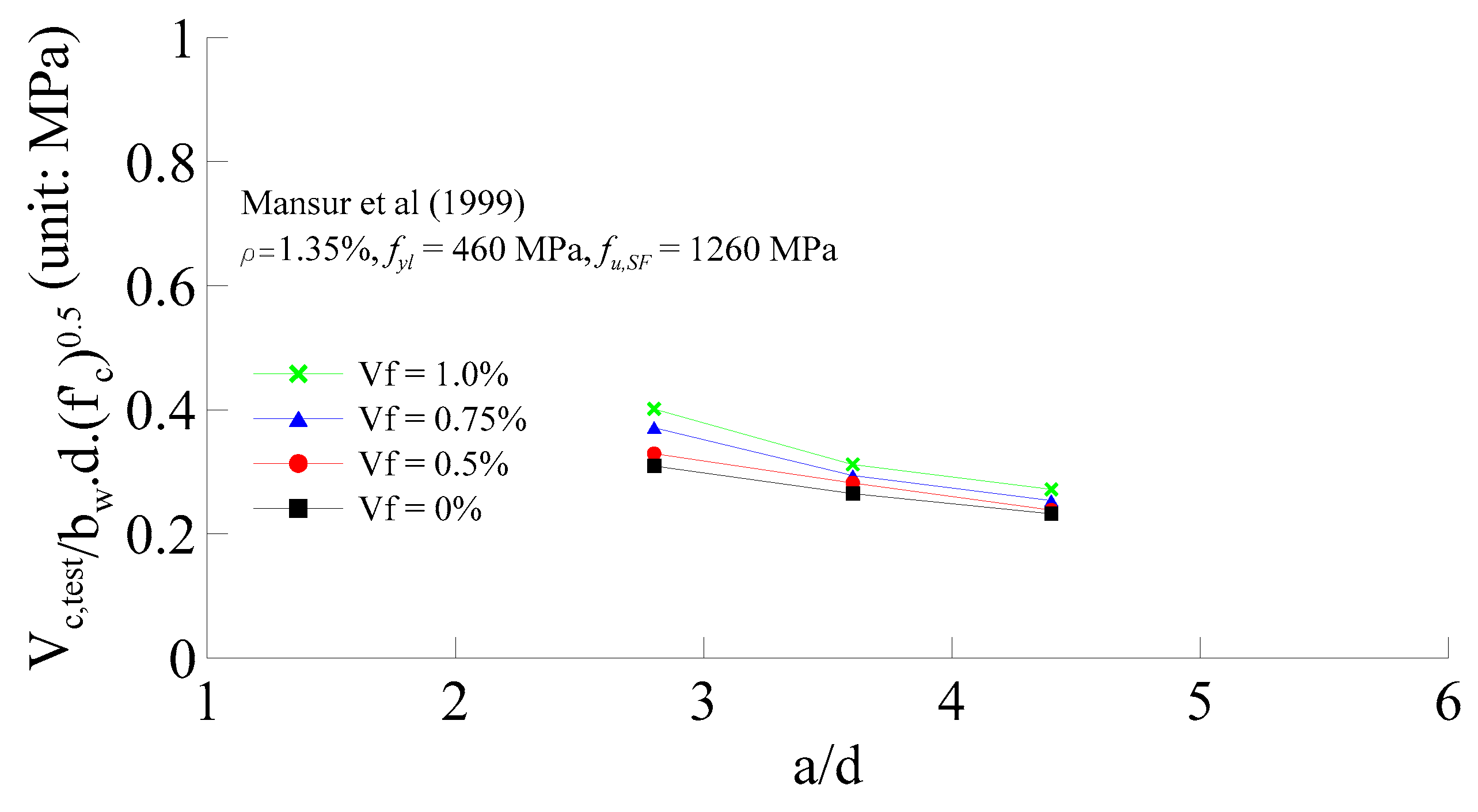

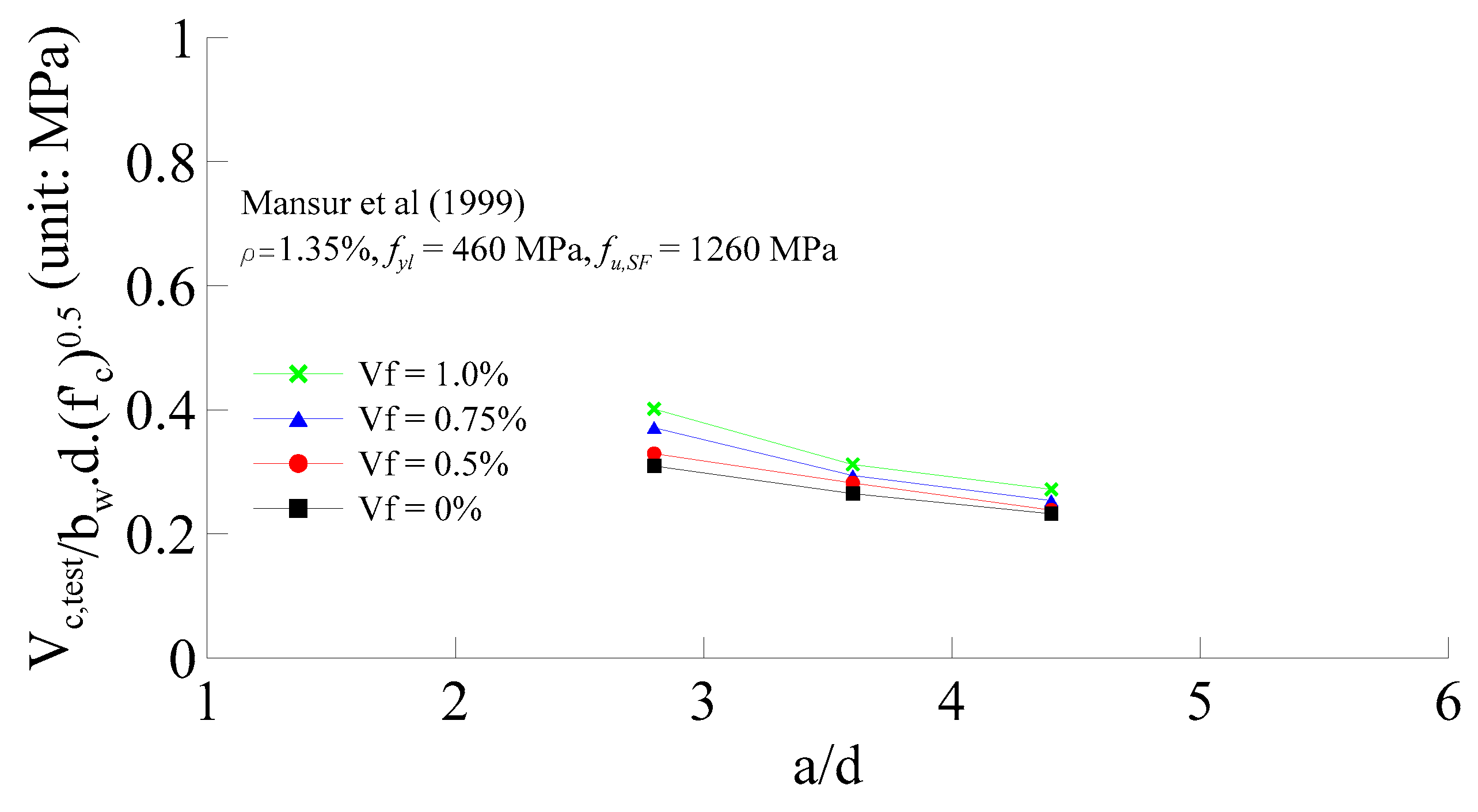

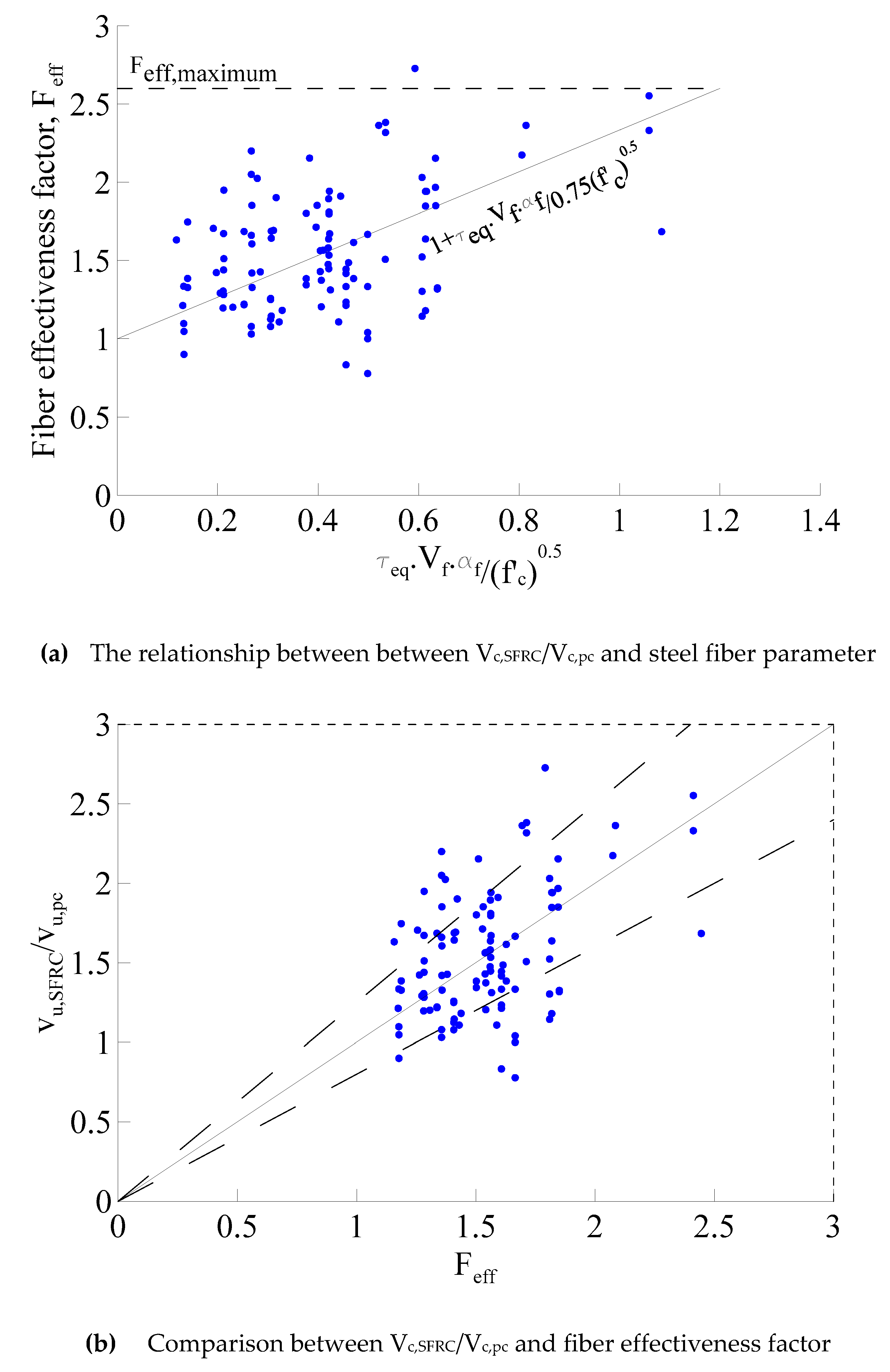

Applied Sciences Free Full Text Shear Strength Prediction Equations And Experimental Study Of High Strength Steel Fiber Reinforced Concrete Beams With Different Shear Span To Depth Ratios Html

Shear yield strength equation

Shear yield strength equation-Mathematically expressed von mises stress formula is used to find the yield strength of any ductile material You can refer the below von mises stress equation to find σ vJust, multiply normal stresses (σ x) and (σ y)Then square the shear stress (t xy) and multiply it with 3Now add the two derived values along with the square of normal stress (σ y)Maximum shear stress=((((Stress acting along x directionStress acting along y direction)^2)(4*(Shear Stress^2)))^05)/2

Failure Strength Sf From Re Rm R 0 2 E And Efailure

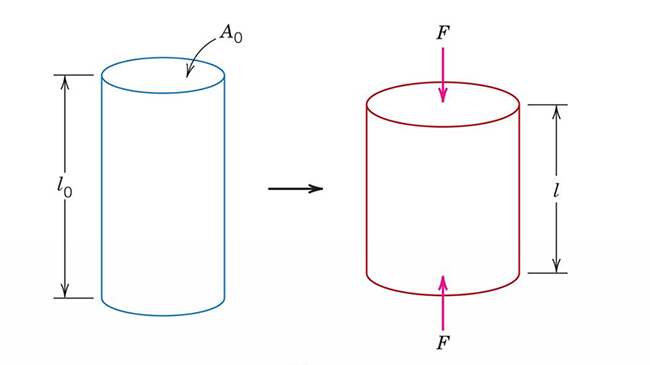

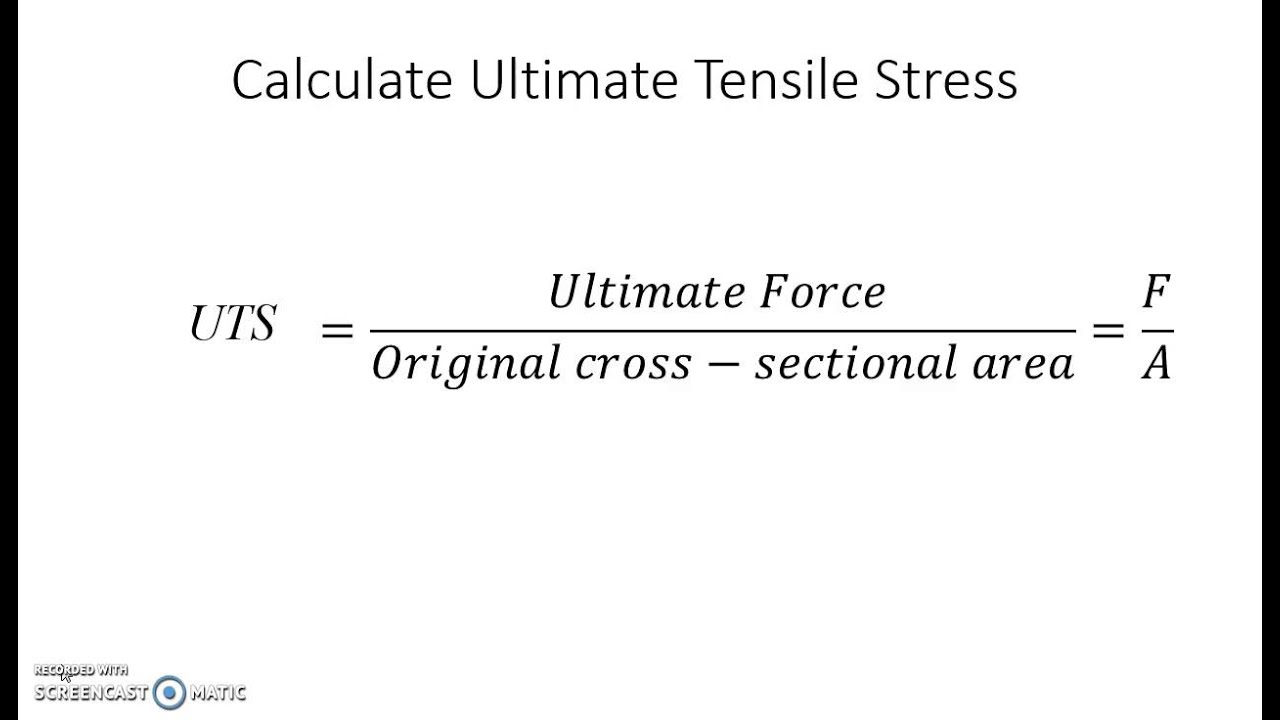

Shear Strength First, find the ultimate tensile strength using the formula above Take that value and multiply it by 60% (060) It is important to understand that this value is only an estimate B8) states that shear strength is approximately 60% of the minimum tensile strengthA = the crosssectional area of material with area perpendicular to the applied force vector;Gave almost the same value of shear strength under saturated condition;

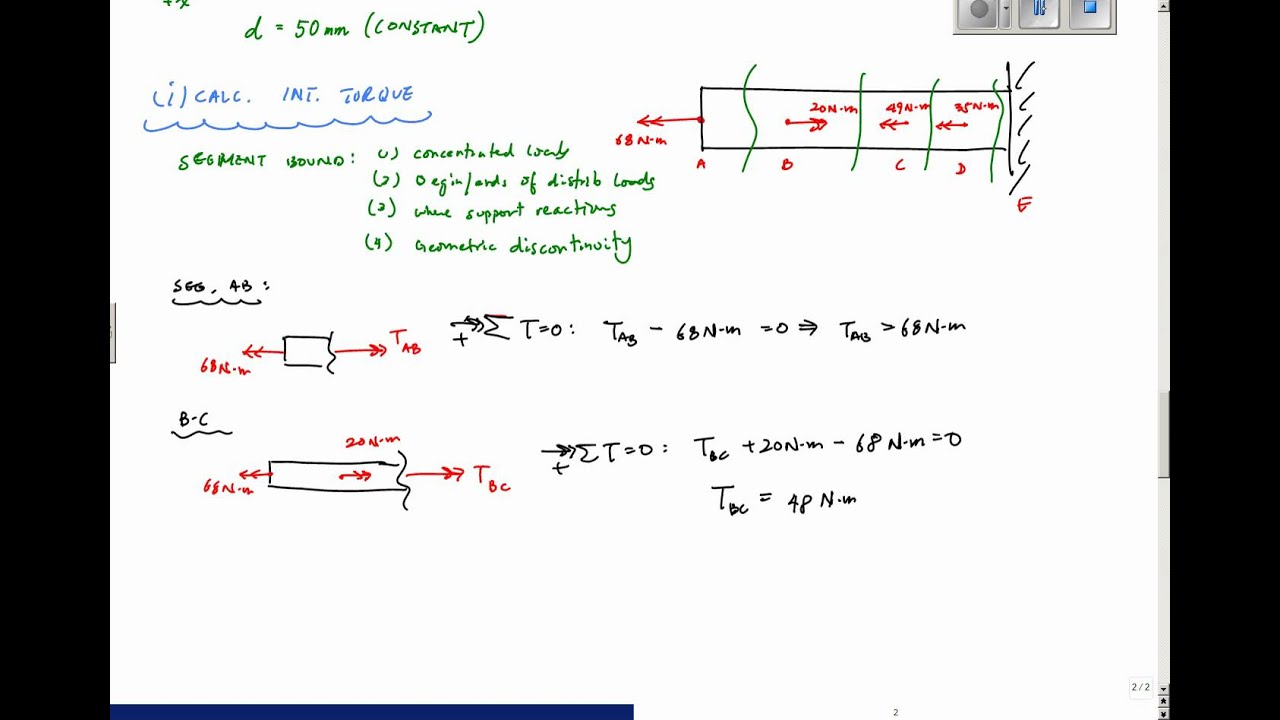

• Torsional Fatigue Strength under fluctuating stresses!Shear (beams) = 15 or 167 shear (bolts) = 0 (tabular nominal strength) shear (welds) = 0 L b is the unbraced length between bracing points, laterally L p is the limiting laterally unbraced length for the limit state of yielding L r is the limiting laterally unbraced length for the limit state of inelastic lateraltorsionalFor example, aluminum has a yield strength of 14,000 pounds per square inch (or psi), copper has a yield strength of 10,000 psi, and steel, being an alloy of several different materials, has a

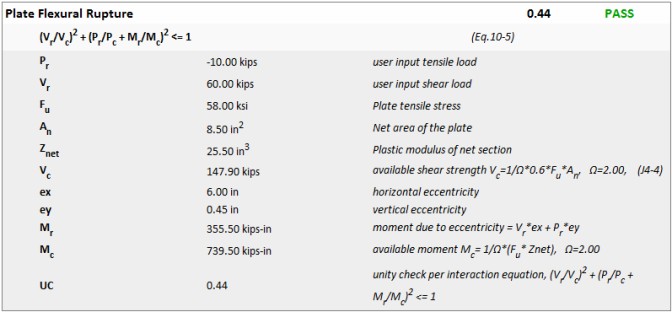

Additionally, the shear strength of the base metal must also be considered φ Rn = 09 x 06 Fy x area of base metal subjected to shear where, Fy is the yield strength of the base metal For example T Elevation Plan T Elevation Plan Strength of weld in shear Strength of base metal = 075 x 0707 x a x Lw x fw = 09 x 06 x Fy x t x LwPermissible Value of Maximum Shear Stress calculator uses Maximum shear stress=05*Tensile Yield Strength/Factor of safety to calculate the Maximum shear stress, The Permissible Value of Maximum Shear Stress formula is defined as the stresses that are located close to the blade surface in the region where viscous residual is calculated using kε approachHow is shear strength calculated?

Solidworks Simulation What Is Von Mises Stress Part 2 Of 2 Designpoint Blog

Intro To Fea

To reduce the strength in the Marin equation (See Sections 69 and 614)!The ultimate strength design method is similar to LRFD There is a nominal strength that is reduced by a factor which must exceed the factored design stress For beams, the concrete only works in compression over a rectangular "stress" block above the na from elastic calculation, and the steel is exposed and reaches the yield stress, F y613,14 (Summary) Torsional Fatigue Strength under fluctuating Stresses & Combine loading!

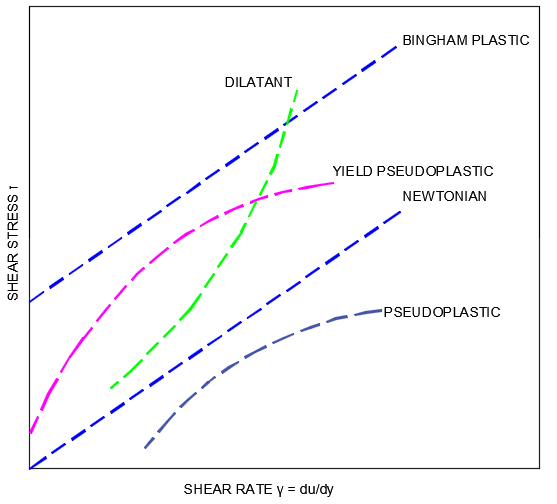

Non Newtonian Fluids Fluidflow Fluidflow

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Grade 8 bolts exhibit greater tensile, yield, and shear strength as well as greater fatigue resistance and, just as important, are capable of greater torque specs and therefore much greater preload and clamping strength There exists an often quoted myth, that Grade 5 bolts are better in shear than Grade 8 since they will bend before breakingIn Goodman diagram!!!a=(K f) Bending (!Yield Strength (psi) Min 44 15% – 1/2 Hard Rb 40 26,000 179 Shear loads and tensile loads are the primary forces acting on a threaded fastener Shear strength of alloy steel is approximately 60% of its ultimate tensile strength " The minimum head diameter for #10 and #12 screws is 3/8 3 9 Grade 2, Grade 5 and Grade 8 Bolts

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

Applied Sciences Free Full Text Shear Strength Prediction Equations And Experimental Study Of High Strength Steel Fiber Reinforced Concrete Beams With Different Shear Span To Depth Ratios Html

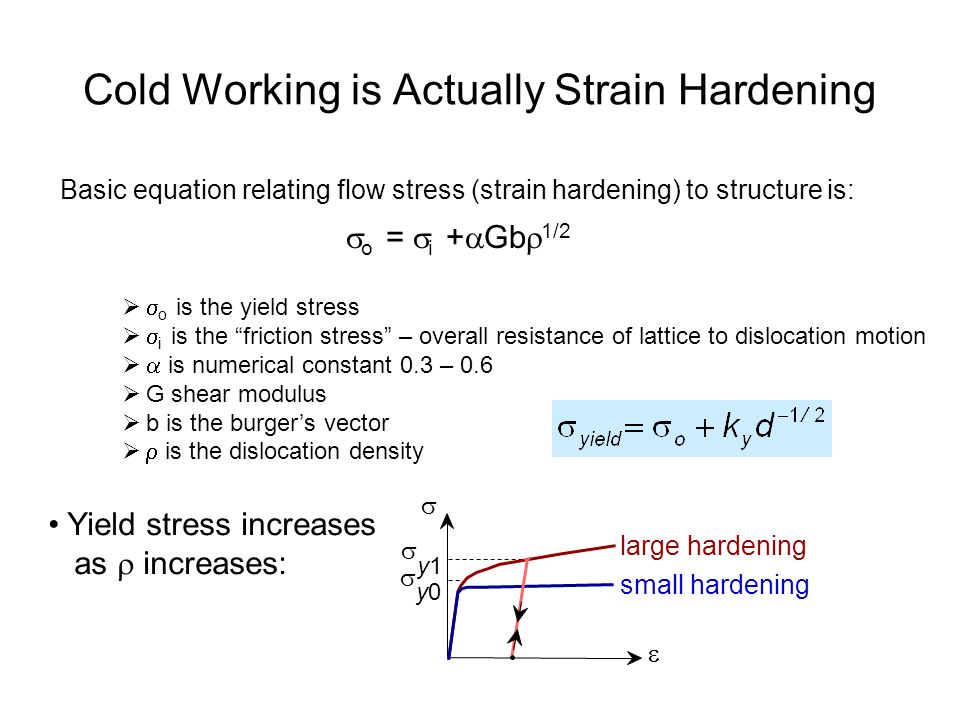

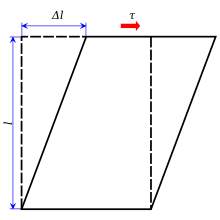

Torsion induces pure shear Disregarding the finer point of yield versus tensile strength, the question concerns the relationship between uniaxial stress and shear stress One way to derive that is to use the von Mises yield criterion To see whatSy ut su ut S S S S 0577 067 = = Note!A lateral deformation is observed in the object when a shear force is applied to it The elastic coefficient is known as shear modulus of rigidity Shear modulus rigidity is the measurement of the rigidity of the object and it is obtained by measuring the ratio of shear stress of the object to the shear strain of the object Shear Modulus Formula

.jpg)

Yield Stress Calculation Methods

Stress Strain Curve Wikipedia

τ = shear stress on dowel pin psi, MPa, τ A = allowable shear stress psi, MPa, s u = Shear or yield strength of dowel pin material psi, MPa, f os = Factor of safety for dowel pin and boards, typical 2 or greater, d = pin diameter in, mm, p 1 = pressure in the top board psi, MPa, p 2 = pressure in the bottom board psi, MPa,Matter Index Shear Stress vs Tensile Stress Relationship between Shear stress and tensile Stress Ultimate Tensile Strength = S u, Ultimate Shear Strength = S su, Tensile Yield Strength = S yp, Shear yield point = S syp Note The relationships below are very approximate for use only as an rule of thumb estimate if no other source of information is availableFEXX = yield strength of weld material Fn = nominal strength in LRFD = nominal tension or shear strength of a bolt Fp = allowable bearing stress Ft = allowable tensile stress Fu = ultimate stress prior to failure Fv = allowable shear stress Fy = yield strength Fyw = yield strength of web material FS = factor of safety g = gage spacing of

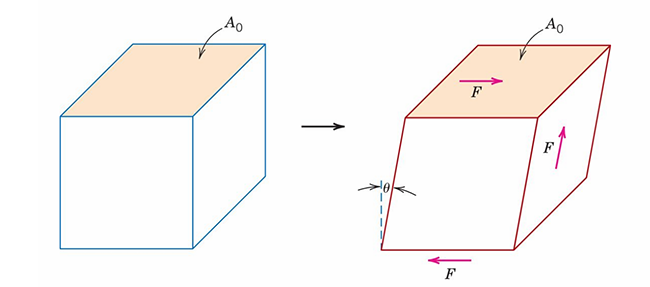

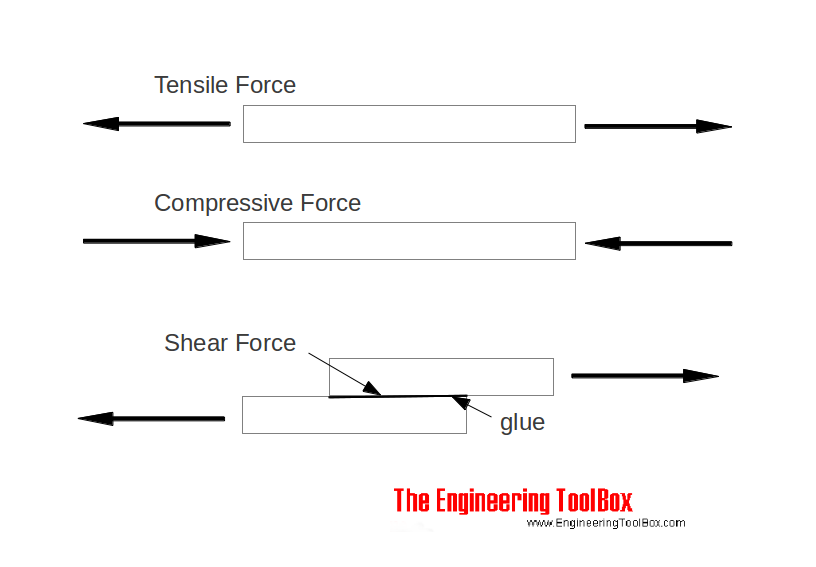

Tensile Compressive Shear And Torsional Stress Matse 81 Materials In Today S World

Von Mises Stress Calculator For Ductile Materials Mechanicalbase

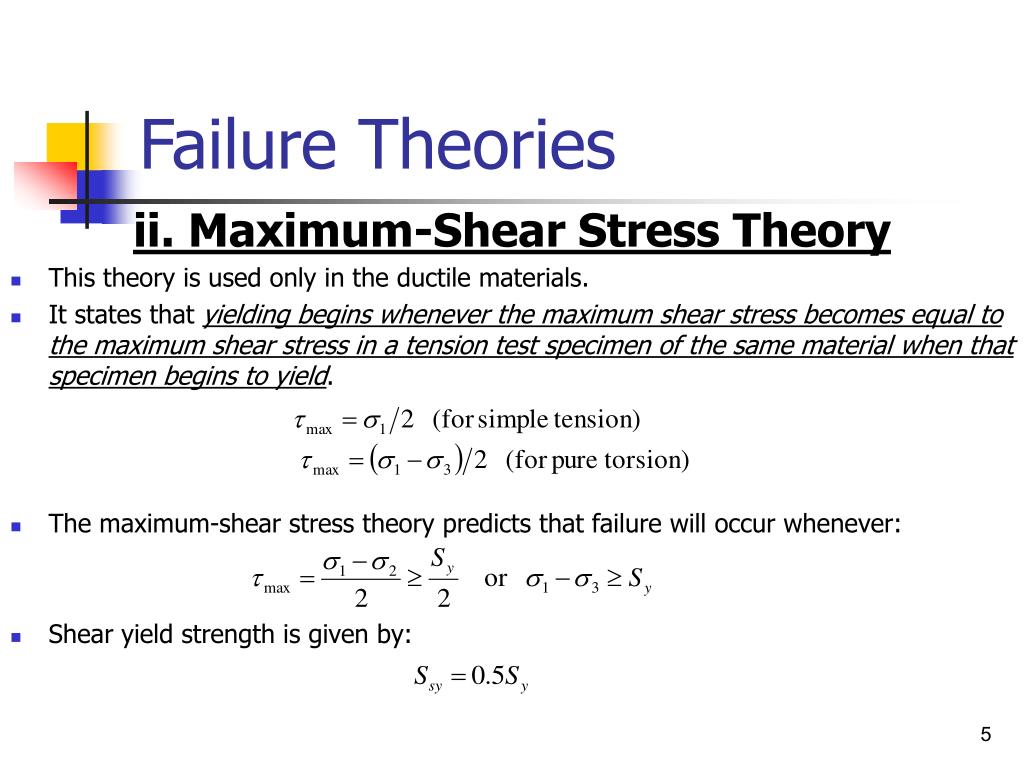

Maximum value of shear stress developed in the body > Yield strength in shear under tensile test ie value of shear stress corresponding to the yield point of the material Let us consider that σ 1 , σ 2 and σ 3 are the principle stresses at a point in material and σ t is the principle stress in simple tension at elastic limitThe material Cert shows only Yield strength 121,000 PSI and Tensile strength 161,000 PSI The mill company said AMS 5732 does not call for shear strength I dont have the spec, and It would take a day to get one what is the formula to convert Yield strength to Shear strength?Beam shear Beam shear is defined as the internal shear stress of a beam caused by the shear force applied to the beam

Spring Minimum Tensile Strength Calculator

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

In this formula, Maximum shear stress uses Yield Strength We can use 3 other way(s) to calculate the same, which is/are as follows Maximum shear stress=(Largest principal stressSmallest principal stress)/2;Fn = Nominal shear strength, Fv = 050 Fu for bolts when threads are excluded from shear planes, ie A325X or 90X In addition, when a bolt carrying load passes through fillers or shims in a shear plane, the provisions of LRFD section J36 apply Values of design shear strength for A325, 90, and A307 are listed in LRFD Table 710 7The average shear strength obtained under the stress of 1 kg/cm2 was 0627 kg/cm2 and the coefficient of varia tion was about 7 % (2) Although shear strength was expected to be affected by soil properties such as clay mineral composition, humus con

Intro To Fea

Mechanics Of Materials Stress Mechanics Of Slender Structures Boston University

Hence, we can express shear modulus as \(Shear Modulus G= F l A \Delta x\) Solved Examples for Shear Modulus Formula Q1 The thickness of a metal plate is 03 inches We drill a hole of the radius of 06 inches on the plate If, the shear strength is \(FA=4 \times10^4\) lb square inch, determine the force we need to make the holeFor mechanical engineering strength design applications it is accepted that shear strength is approximately 60% of tensile strength If UTS = 'x' (Ultimate Tensile Strength) This is the value usually reported in handbooks then USS = 60% of 'x';USS Ultimate Shear Strength, UTS Ultimate Tensile Strength, SYS Shear Yield Stress, TYS Tensile Yield Stress Material Ultimate stress Ultimate stress Fiberglass/epoxy (23 o C) 7 26 When values measured from physical samples are desired, a number of testing standards are available, covering different material categories and testing

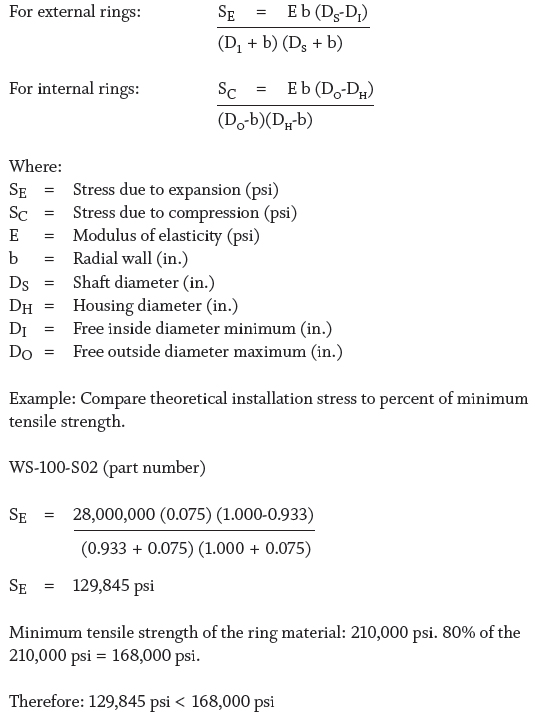

Careful Calculations Affect Ring Design

Failure Strength Sf From Re Rm R 0 2 E And Efailure

Yield Strength in Shear (maximum shear Stress theory) calculator uses Shear Yield Strength=Factor of safety*Maximum Principle Stress to calculate the Shear Yield Strength, The Yield Strength in Shear (maximum shear Stress theory) formula is defined as the strength of a material or component against the type of yield or structural failure when the material or component fails in shearCompressive yield stress is measured in a manner identical to that done for tensile yield strength When testing metals, it is defined as the stress corresponding to 0002 in/in plastic strain For plastics, the compressive yield stress is measured at the point of permanent yield on the stressstrain curveClause 2 of AWS D11 requires that the minimum tensile strength of the filler metal be multiplied by 030 to obtain the allowable shear stress on the weld The calculation is the exact same as when calculating the strength of a transverse fillet weld , except for the safety factor

Q Tbn And9gcq Lokv6u6biweu7e6sd5mb7neolnaw Dcdbogfctf 8hvcdutp Usqp Cau

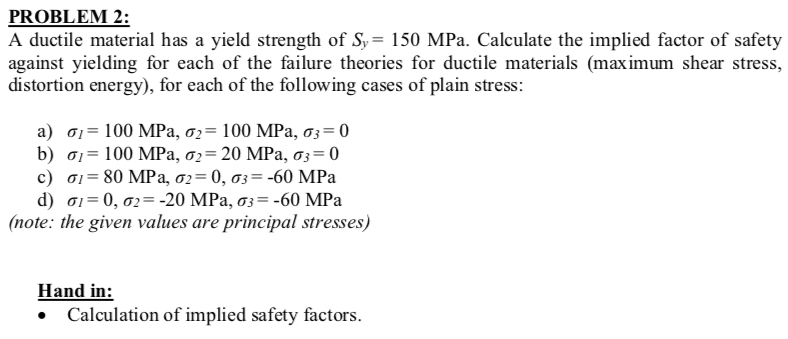

Solved A Ductile Material Has A Yield Strength Of Sy 150 Chegg Com

FEXX = yield strength of weld material Fn = nominal strength in LRFD = nominal tension or shear strength of a bolt Fp = allowable bearing stress Ft = allowable tensile stress Fu = ultimate stress prior to failure Fv = allowable shear stress Fy = yield strength Fyw = yield strength of web material FS = factor of safety g = gage spacing ofShear Strength nThe web will completely yield long before the flanges begin to yield Because of this, yielding of the web represents one of the shear limit states nTaking the shear yield stress as 60% of the tensile yield stress nThis will be the nominal strength in shear provided there is no shear buckling of the webEg, the weight of an earthfilled dam or dike may cause the subsoil to

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

Tresca Stress Forum

F = the force applied;Dividing the shear flow by the thickness of a given portion of the semimonocoque structure yields the shear stress Thus, the maximum shear stress will occur either in the web of maximum shear flow or minimum thicknessAlso constructions in soil can fail due to shear;Shear Strength First, find the ultimate tensile strength using the formula above Take that value and multiply it by 60% (060) It is important to understand that this value is only an estimate B8) states that shear strength is approximately 60% of the minimum tensile strength

What Is The Shear Stress Of Mild Steel Value And How Is It Calculated Quora

Strength

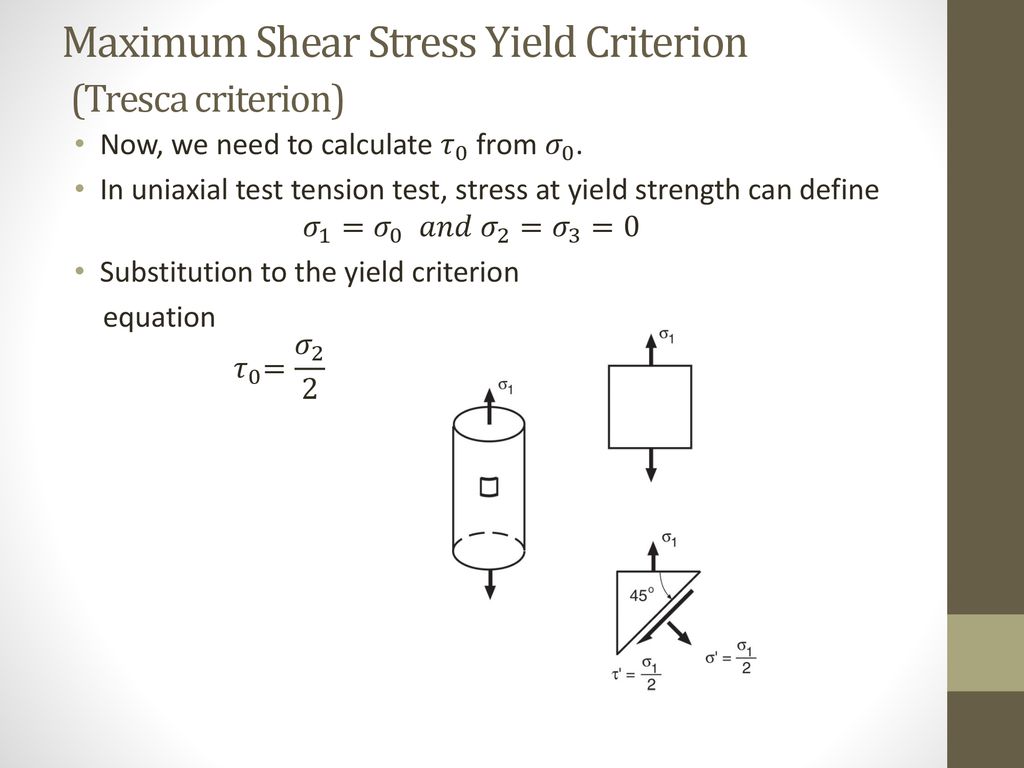

In a triaxial stress state, this theory predicts that yielding will occur whenever onehalf the algebraic difference between the maximum and minimum stress is equal to onehalf the yield stress Where σ1 > σ2 > σ3, the maximum shear stress is ( σ1 – σ3 )/2 Yielding will begin when σ 1 − σ 3 2 = F y 2Grade 8 bolts exhibit greater tensile, yield, and shear strength as well as greater fatigue resistance and, just as important, are capable of greater torque specs and therefore much greater preload and clamping strength There exists an often quoted myth, that Grade 5 bolts are better in shear than Grade 8 since they will bend before breakingGeneral shear stress The formula to calculate average shear stress is where τ = the shear stress;

Www Aisc Org Globalassets Aisc Manual 15th Ed Ref List Specification For The Design Of Steel Hollow Structural Sections Pdf

Isbt212 04 3 Stress And Strain Proportional Limit And Yield Strength Youtube

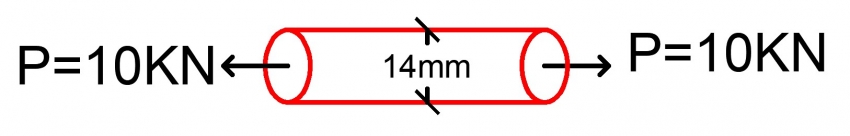

Ie 06*UTS If you are looking at YS (Yield Strength) then SYS = 60% of YS;Average Mechanical Properties of Typical Engineering Materials a (US Customary Units) Materials Specific Weight (lb, in 3) Moduls of Elasticity E (10 3) ksi Modulus of Rigidity G (10 3) ksi Yield Strength (ksi) S Y Tens Comp b Shear Ultimate Strength (ksi) S u TensGiven total force at failure (F) and the forceresisting area (eg the crosssection of a bolt loaded in shear), ultimate shear strength is τ = F A = F π r b o l t 2 = 4 F π d b o l t 2 {\displaystyle \tau ={\frac {F}{A}}={\frac {F}{\pi r_{bolt}^{2}}}={\frac {4F}{\pi d_{bolt}^{2}}}}

Empirical Equations And Code Provisions For Shear Strength Of Concrete Download Table

Tensile Compressive Shear And Torsional Stress Matse 81 Materials In Today S World

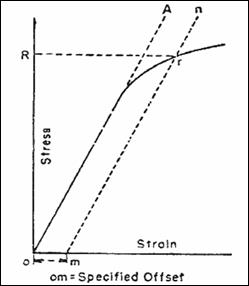

Torsional strength is the maximum amount of torsional stress a body can withstand before it fails, divided by its cross sectional area This property is relevant for components such as shafts Yield Strength Yield strength is defined as the stress at which a material changes from elastic deformation to plastic deformationA) Benig (K fThe shear strength is then readily determined as half the unconfined compressive strength of undisturbed samples If the change in stress will ultimately lead to swelling, the shear strength may decrease with time, the use of the unconfined compression or triaxial Qtests (unconsolidated undrained) may give satisfactory results for the

Shear Strength An Overview Sciencedirect Topics

Ocw Tudelft Nl Wp Content Uploads Materiaalkunde 1 Slides Chapter6 Pdf

Where σ 1 = xdirection max shear stress, σ 2 = ydirection max shear stress and σ(y) = yield stress References Engineering Toolbox Stress, Strain and Young's ModulusI think you mean the difference between the yield strength of a material in tensile (math\sigma_{yt}/math) and yield strength of a material in shear (math\sigma_{ys}/math) Take a bar of a metal subjected to the forces as in two scenariosIn engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shearA shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force When a paper is cut with scissors, the paper fails in shear

Www rec Net In Me Design 19 Pdf

Calculate Yield Stress Youtube

USS Ultimate Shear Strength, UTS Ultimate Tensile Strength, SYS Shear Yield Stress, TYS Tensile Yield Stress Material Ultimate stress Ultimate stress Fiberglass/epoxy (23 o C) 7 26 When values measured from physical samples are desired, a number of testing standards are available, covering different material categories and testingShear Strength First, find the ultimate tensile strength using the formula above Take that value and multiply it by 60% (060) It is important to understand that this value is only an estimate Unlike tensile and yield strengths, there are no published shear strength values or requirements for ASTM specificationsSo we need to relate it to the axial yield strength σ 0 For a given material under axial load where σ 1 = σ 0 and σ 2 = σ 3 = 0, we assume that yielding occurs when the octahedral shear stress is equivalent to the octahedral stress criterion This means we can combine Eq 2 and 4 to get the octahedral stress criterion in terms of the

Drvsr Files Wordpress Com 17 12 Unit 5 Lecture 3 Pdf

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

How is shear strength calculated?The Yield strength the amount of stress that a material can undergo before moving from elastic deformation into plastic deformation is typical 250 MPa for steel Example Shear Stress in a Beam with Point LoadAdditionally, the shear strength of the base metal must also be considered φ Rn = 09 x 06 Fy x area of base metal subjected to shear where, Fy is the yield strength of the base metal For example T Elevation Plan T Elevation Plan Strength of weld in shear Strength of base metal = 075 x 0707 x a x Lw x fw = 09 x 06 x Fy x t x Lw

Von Mises Yield Criterion Wikipedia

Thread Yield And Tensile Strength Equation And Calculator Engineers Edge Www Engineersedge Com

Yield Strength (psi) Min 44 15% – 1/2 Hard Rb 40 26,000 179 Shear loads and tensile loads are the primary forces acting on a threaded fastener Shear strength of alloy steel is approximately 60% of its ultimate tensile strength " The minimum head diameter for #10 and #12 screws is 3/8 3 9 Grade 2, Grade 5 and Grade 8 BoltsMatter Index Shear Stress vs Tensile Stress Relationship between Shear stress and tensile Stress Ultimate Tensile Strength = S u, Ultimate Shear Strength = S su, Tensile Yield Strength = S yp, Shear yield point = S syp Note The relationships below are very approximate for use only as an rule of thumb estimate if no other source of information is availableOr would be better to send the material for shear strength test

Cold Working Is Actually Strain Hardening Basic Equation Relating Flow Stress Strain Hardening To Structure Is O I Gb 1 2 Yield Stress Increases Ppt Download

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Material Checks

Ppt Failures Due To Static Loading Powerpoint Presentation Free Download Id

113 Questions With Answers In Yield Strength Science Topic

Ch 2 Stress Strains And Yield Criterion

Tensile Strength An Overview Sciencedirect Topics

Www rec Net In Me Design 19 Pdf

Tensile Compressive Shear And Torsional Stress Matse 81 Materials In Today S World

.jpg)

Yield Stress Calculation Methods

Http Faculty Mercer Edu Jenkins He Documents Mae322lecture3failuretheoriescoulomb Mohr Pdf

Engineering Purdue Edu Ahvarma Ce 470 S17 Ce470 Aisc Chapter 5 Ce470 Ch 5b Beam Shear Design Pdf

Yield Strength Strength Mechanics Of Materials Engineers Edge

Tensile Compressive Shear And Torsional Stress Matse 81 Materials In Today S World

Yielding And Fracture Under Combine Stresses Ppt Download

Lecture Notes

Q Tbn And9gcqdhkmo7hherjjmwerev9j1zxqfwpmjetj5gvnkildcbtyau41x Usqp Cau

Yield Strength Yield Point Stress Strain Curve

Cantilever Beam Worked Example

Shear Yield Strength An Overview Sciencedirect Topics

Doitpoms Tlp Library Slip In Single Crystals Slip Geometry

Engineering Purdue Edu Ahvarma Ce 470 S17 Ce470 Aisc Chapter 5 Ce470 Ch 5b Beam Shear Design Pdf

Yield Strength Of Plastics Basic Principles The Tensile Test And Material Property Table Engineeringclicks

Perfect Equation Parameters Description Incl Units Tex Latex Stack Exchange

Www3 Nd Edu Cneal Planetearth Chapt 11a Rock Mechanics Pdf

Why Your Nds Nail Calcs Could Be Wrong And What You Can Do About It Simpson Strong Tie Structural Engineering Blog

Www Dartmouth Edu Cushman Courses Engs171 Usefulsolutionsforstandardproblems Pdf

.jpg)

Yield Stress Calculation Methods

Strength Of Materials Basics And Equations

Shear Strength Wikipedia

What Is Maximum Shear Stress Theory And The Mathematical Expression For It Quora

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Helical Linear Spring Shear Stress T Calculator

Applied Sciences Free Full Text Shear Strength Prediction Equations And Experimental Study Of High Strength Steel Fiber Reinforced Concrete Beams With Different Shear Span To Depth Ratios Html

Shafts In Torsion Mechanical Properties Of Materials

Stress Strain Curve How To Read The Graph

Failure Criteria For Ductile Materials

Yield Engineering Wikipedia

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Calculate The Maximum Shear Stress Thestructuralengineer Info

.jpg)

Yield Stress Calculation Methods

Metal Mechanical Properties Chart Shear Strength Tensile Strength Yield Strength Machinemfg

Cdn Technologynetworks Com Tn Resources Pdf Wp1416understandyieldstressmeas Pdf

D S 1 Lesson 22 Shear Stress In Beams

Ch 2 Stress Strains And Yield Criterion

Ch 2 Stress Strains And Yield Criterion

Cdn Technologynetworks Com Tn Resources Pdf Wp1416understandyieldstressmeas Pdf

What Is The Shear Strength Coefficient For Cold Rolled Steels

Tensile Stress S An Overview Sciencedirect Topics

Tensile Stress Compressive Stress Shear Stress And Bulk Modulus Youtube

Screw Thread Calculations Roy Mech

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Ch 2 Stress Strains And Yield Criterion

Shear Stress Is 0 5 Of Tensile Stress Is It Applicable In All Cases Quora

Critical Resolved Shear Stress Wikipedia

Www Usna Edu Naoe Files Documents Courses En380 Course Notes Ch10 Deformation Pdf

D S 1 Lesson 22 Shear Stress In Beams

Q Tbn And9gctmp5gswalnvf7kbuvd5qb30kdyiz41ue308y4uzud Fxdycd3q Usqp Cau

Tensile Stress Strain Compressive Stress Shear Stress Basic Introduction Youtube

Critical Resolved Shear Stress Wikipedia

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

What Is Shear Strength Matmatch

Ch 2 Stress Strains And Yield Criterion

Http Www Eng Auburn Edu Htippur Mech6300 Failure theories Pdf

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Shear Yield Stress An Overview Sciencedirect Topics

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Stress Strain And Young S Modulus

Drvsr Files Wordpress Com 17 12 Unit 5 Lecture 3 Pdf

Shear Stress Due To Torsion Example 1 Mechanics Of Materials Youtube

コメント

コメントを投稿